introduce

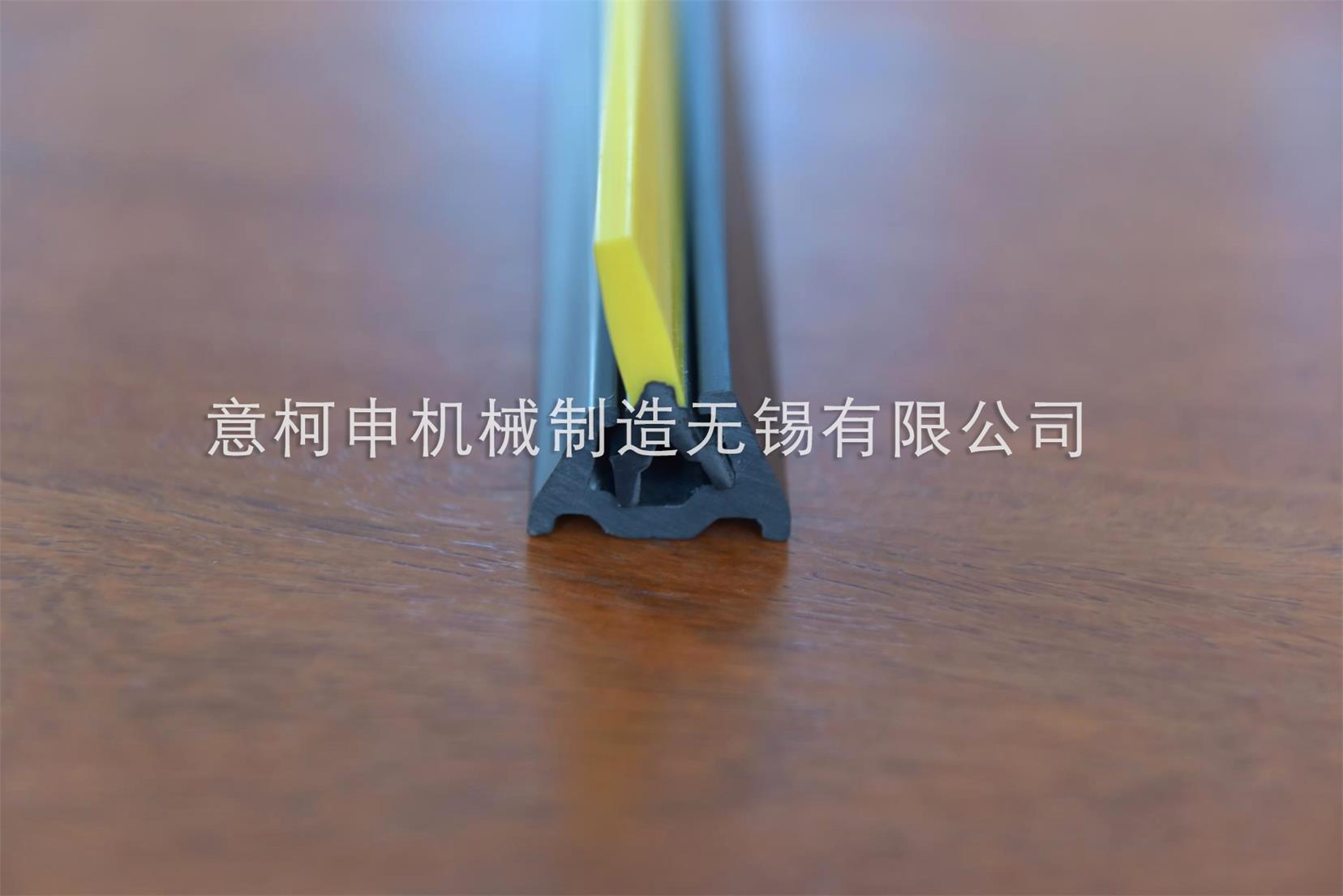

Plastic coextrusion is an extrusion process for plastic profiles. It is a product of two different colors, which is made of two different color materials (material can be different) transported to extrusion equipment through different channels.

Main points of processing

The two materials that are invested must be similar or identical in nature, otherwise the combination is not close because of poor affinity. Double color coextrusion process is mainly used for processing steel profiles. Plastic Co extruded plastic profiles can be divided into homogeneous and non homogeneous coextrusion. At present, the main application is non homogeneous co extrusion, subdivided into PVCASA, PVC-PMMA two. The best and most mature technology, PVCASA effect. It also can be used for PE pipe production.

Advantage

Plastic coextrusion products have two different colors or materials, and have the common advantages of two kinds of materials. In building decoration, it can also effectively save the cost while meeting the demand of color and performance.